Wideband tubular MMM transducers

Types: MPI-ITT-28 and MPI-ITT-40

MPI Tubular Submersible Transducers are general use cleaning and liquid processing transducers intended for use with Mastersonic MMM Power Supplies.

Features of MPI Tubular Submersible Transducers

- High density and uniform cavitation, no standing waves (From Hz to MHz)

- Superior and fast cleaning effects.

- Corrosion free, water proof design.

- Easy and simple to install in any available tank or reservoir thanks to its tubular shape and range of lengths available.

- Original and unique design (patent pending)

- Compared to conventional submersible transducers MMM tubular transducers have several times longer operating life.

- Good for applications in MMM technology, and in constant frequency applications

- Continuous operating power: Different models from 300 W to 1500 Watts and higher on custom order.

- Available in Flexible hose and Through-tank-wall models for maximum mounting versatility.

- Best results will be achieved with MMM generators

Applications

Excellent for sonochemistry, cleaning, waste water processing and a whole range of new applications arising from MMM technology, eg. filtering, nano-powders technologies, catalysts and free radical creation.

Since the cavitation occurs uniformly and omni-directionally, all around the MMM tube, sonic and ultrasonic energy distribution in the tank is very uniform, creating excellent cleaning and liquid processing effects. Strong, even cavitation is achieved along the entire tube length.

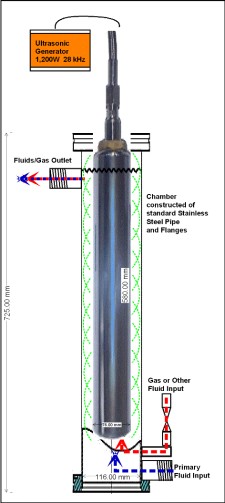

Construction and installation of tubular transducers

This submersible transducer array is constructed from high-grade stainless steel with hard-Cr plating for maximum cavitation resistance (SUS304 and 316L with 20 microns hard Cr plate).

The Flexible Hose version allows the Tube Transducer to be submerged in a tank in any position and orientation (vertical, horizontal, diagonal). This model may also be easily moved from tank to tank. The Through Tank Wall version allows for secure and fixed mounting to a tank wall or base, again in any position and orientation.

Transducers can be installed either in tanks or in tubes for through-flow in-line processing. These diagrams show typical installations, many others are possible to suit all kinds of liquid-processing application.

Advantages of MMM

- MMM (multifrequency) driving causes the transducer to radiate omni-directionally over its integral external surface and prevents the creation of standing waves. This provides more useful power and much lower surface erosion damage than for traditional transducers operating at constant frequency.

- When driven by an MMM generator the unique construction and shape of these transducers stimulate a full range of wideband harmonic frequencies and ultrasonic effects in liquid.

- The output power of MMM tubular transducers is not significantly affected by immersion depth, capacity of a bath or sonoreactor, load and liquid temperature variations or pressure.

Standard models

Many other models available, plus specials on request

Specification for ordering type ITT (integrated tubular transducer)

|

||||

| MPI model number: | ITT-28-600 | ITT-28-900 | ITT-28-1200 | ITT-28-1500 |

|---|---|---|---|---|

| Effective power (watt) | 600 | 900 | 1200 | 1500 |

| Frequency (kHz) | 28 | 28 | 28 | 28 |

| Dimensions: Dia x L (mm) | Φ76.3 x 310 | Φ76.3 x 460 | Φ76.3 x 580 | Φ76.3 x 680 |

| 40kHz models: | ||||

| MPI model number: | ITT-40-600 | ITT-40-900 | ITT-40-1200 | ITT-40-1500 |

| Effective power (watt) | 600 | 900 | 1200 | 1500 |

| Frequency (kHz) | 40 | 40 | 40 | 40 |

| Dimensions: Dia x L (mm) | Φ60.5 x 310 | Φ60.5 x 460 | Φ60.5 x 580 | Φ60.5 x 680 |

Contact us for more information about special sizes made to suit customer specifications.